Hunan Xiangdian Changsha Pump Co., Ltd. (Changsha Pump Factory) was founded in 1951. It has been engaged in the research and development and manufacture of pump products for more than 60 years. It is one of the top 500 machines in China and one of the top 500 manufacturers in China.

Over the years, the company's products have won nearly 40 national scientific research awards: 69APMA vertical inclined flow pump, large thermal power generator set of equipment won major technical equipment awards, 200D43 mine drainage pump won the energy-saving product award, S150-50 single-stage double-suction centrifugal pump won the high-quality product award, 28QZ-7.0 axial submersible pump won the new product award, vertical inclined flow seawater circulation pump, 100FN-65 melted urine. Sulphur pump won the prize of scientific and technological progress. The company's products have won the award of excellent mechanical and electrical equipment, the best quality unit and excellent suppliers in Dongshen Project, Baosteel Project, Shanghai Raw Water, Shandong Electric Power and other major national projects. A certain type of product of national defense military industry won the second prize of China's shipbuilding industry. The company's C.B brand product logo was rated as a trustworthy brand for Hunan consumers. The C.B brand vertical diagonal pump was awarded Hunan famous brand products in 2004, 2009 and 2012.

In recent years, the company has devoted itself to product restructuring and achieved fruitful results in the development of new products: LKXA.B.C vertical inclined flow pump, XJ medium-open centrifugal clean water pump, million kilowatt conventional island concrete volute pump of nuclear power plant won the gold prize at China International Fluid Machinery Exhibition; WNB series dredger pump, A.B.C vertical multi-stage condensation pump won the silver prize. The company's research and development project of dual-phase stainless steel impeller technology for seawater circulating pump in MW nuclear power plant won the second prize of China Machinery Industry Science and Technology, which indicates that the company has fully mastered the manufacturing technology of large dual-phase stainless steel impeller. The first AP1000 waste heat removal pump developed jointly by the company and Shanghai Nuclear Engineering Research and Design Institute has been successfully developed, which contributes to the localization of AP1000 waste heat removal pump in China.

Since the 1980s, the company has adhered to the road of introduction and independent innovation. It has established good technical cooperation relations with Flowserve, Ingersoll-Rand, Ellicott, Ebara, Hitachi, Kubote, Mapper, Netherlands and other international well-known pump companies. At present, the products have formed more than 50 series, more than 1000 varieties and more than 2500 specifications. The main products are: large vertical oblique flow pump, vertical condensation pump, nuclear power pump, marine dredging pump, cement volute pump, heat network circulating pump, multi-stage medium-start pump, vertical volute pump, single-stage double suction centrifugal pump, axial flow pump, submersible pump, multi-stage pump, cantilever pump, mud pump, non-blocking pump, sewage pump, etc. The products are widely used in energy, metallurgy, chemical industry, national defense, military industry, building materials, light weight, etc. Textile, urban construction, machinery, agricultural irrigation and drainage, environmental protection and other fields, best-selling throughout the country and exported to more than 50 countries and regions.

In 2006, the company implemented the relocation strategy. It took three years to build the first-class Machine-mounted base (headquarters) and foundry base in Changsha Lugu High-tech Zone and Ningxiang Jingdian District, with complete technology, equipment, production capacity and management system. Using three-dimensional CAD, CAPP, ERP and CAE, PDM, CAM network technology means, from design, manufacturing to management and service to achieve informatization. It has a pump testing center and high-precision testing instruments. It has first-class casting, processing, assembly, testing ability, post-casting, welding, heat treatment ability and analysis and testing means. It can produce 5000 large-scale pump products annually. The company has a perfect quality assurance system, and has obtained ISO 9001 quality assurance system certification, ISO 14001 environmental management system and OHSAS 18001 occupational health and safety management system certification, ISO 10012-1 measurement and testing system certification, scientific research and production of weapons and equipment, acceptance certification, design certification and manufacturing certification of civil nuclear pressure equipment issued by the National Nuclear Safety Administration, etc.

At present, the company carries out the strategy of internationalization and high value-added road, adjusts the product structure, consolidates the traditional market, and develops high-end products in nuclear power, military products, petrochemical, environmental protection and other fields. Following the concept of industry serving the country, the company takes the responsibility of revitalizing the nationalization of major equipment and perseveres towards the goal of leading the industry and world-renowned.

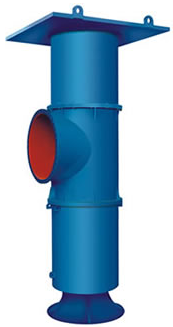

Vertical oblique flow pump

Summary: TKX (S), LKX (S), LBX (S) vertical oblique flow pumps are new products developed by our company in the 1980s by introducing advanced technology from American I-R Company. They are suitable for large thermal power plants and nuclear power plants as circulating pumps, working metallurgical, urban and agricultural water supply and drainage pumps and industrial and mining engineering pumps, which are used for transporting fresh water, rainwater, sewage and seawater below 55 degrees Celsius. Parameter range: Pumps with flow Q 0.20-25 m3/s head H 3-60 m or more can be tested in the test center of our factory. Model Description: 80 LKXC-20A 80-Pump outlet diameter (inch, 2000/25=80) L-means vertical oblique flow pump, T means adjustable blade; K-means pump rotor can be pumped out, B means rotor can not be pumped; X-means pump outlet under the foundation, S means outlet on the foundation; C-pump design sequence; 20-pump design point head; A-means impeller has been cut. Structural type: The pump shaft is installed vertically, the suction inlet is vertical downward, the exhaust outlet is horizontal outward extension, and the rotor components have two forms: extractable and non-extractable. The impeller blade angle of T-type pump can be changed in the operation of the unit. Installation modes are pump and motor installed in two basic layers respectively and pump and motor directly connected in one basic layer. The seal is sealed with packing. Pump suction pool has wet pit type and dry pit type. The axial thrust of the pump is generally borne by the motor, and the small pump can also be borne by the pump itself. The impeller is usually one-stage and can be designed into multi-stage according to the need. The bearings of the pump are rubber bearings and Cylon bearings. When rubber bearings are used, the pump shaft is provided with protective sleeves, which are filled with clean pressure water for lubrication. Material of main parts: Pump shaft is made of high quality carbon steel. The impeller is cast iron or cast steel or stainless steel. The rest are cast iron or steel plate welding. Complete range: complete supply pump, motor and base or mounting pad. When ordering, it is necessary to specify the material required for impeller. If there are special requirements, specific technical requirements can be put forward to the company when ordering.

YJG Vertical Single-stage Single-suction Centrifugal Clean Water Pump

Summary: YJG vertical single stage single suction volute shell centrifugal water pump is a structural improvement of YJ pump. It is suitable for water supply and drainage engineering of large thermal power plant, industry, mining, urban and farmland construction. It is used to transport clean water without solid particles or other liquids whose physical and chemical properties are similar to clear water. The temperature of the transported liquids does not exceed the parameter range of 50 C: flow rate Q 1.0-6.8m3/s head H 13.1-63m model description: YJG44P left-22JA YJG-vertical single-stage single suction volute centrifugal clean water pump 44-suction caliber (mm) is divided by 25, i.e. 44 represents the number of pump suction. The diameter is 1100 mm P, indicating the change of the pump base structure left. From the motor to the pump, the impeller rotates clockwise without marking 22 when it rotates counter-clockwise. The number J obtained by dividing the specific speed of the pump by 10 is the marking of the change of the pump speed A is the marking of the change of impeller diameter, using A, B, C... The difference between impeller models is expressed in terms of I, II... Express. Structural type: The pump is installed vertically with the suction port vertically downward and the spitting outlet horizontally outstretched. The unit is installed in the direct connection of pump and motor, the seal is packed, the bearing adopts rolling bearing, the axial fixing of impeller adopts Huff lock ring structure, the coupling adopts adjustable rigid connection, the impeller is balanced rib structure, and the axial force is borne by the motor. Rotating direction: Seen from the motor to the pump, the pump rotates counterclockwise. If the pump is required to rotate clockwise, add "left" in the prototype number to indicate the difference, and the performance parameters remain unchanged, such as: (YJG36 left -*). Main parts material: impeller: ZG310-570/ZG1Cr13Nil/ZG0Cr13Ni4Mo. Sealing Ring: ZG2Cr13 Axis: 45 Pump Shell: Cast Iron Complete Range: Complete Supply Pump, Motor and Base. When ordering, please specify the impeller material. If there are special requirements for pumps and motors, we can negotiate with the company about the technical requirements.

Summary: Vertical multi-stage condensate pump is a series of products developed by Hitachi Manufacturing Institute in Japan. It is suitable for use as condensate pump in large thermal power plants, including various specifications for 100, 125 (145), 200, 300, 600 and 1000MW turbogenerator units. It can also be used as a pump for pumping other liquids with physical and chemical properties similar to clear water. The temperature of liquids does not exceed 80 C. Parameter Range: Flow Q 230-1920m3/h Head H 74-303m Model Description: B640 (I, II, III) -5B-Initial Double-suction Spiral Centrifugal Condensation Pump 640-Nominal Diameter of Pump Guide Vane Exit mmI-Pump Axial Seal adopts Mechanical Seal II-Pump Body withstands Axial Thrust III-Pump Body withstands Axial Thrust, Pump Axial Thrust The seal adopts mechanical seal 5-pump series structure form: condensate pump is vertical outer cylinder, which has three structural forms: (1) A-initial stage double suction guide vane multi-stage centrifugal condensation pump, (2) B-initial stage double suction helical guide vane multi-stage centrifugal condensation pump, (3) C-initial stage double suction helical oblique flow multi-stage condensation pump unit is installed in direct connection form; It can be borne by the motor or by the pump body. The axial seal of the pump is packed seal, or mechanical seal can be used. Rotating direction: Seen from the motor to the pump, the pump rotates counterclockwise. Material of main parts: First outer cylinder Q235-A/stainless steel impeller 45 steel shell QT450-10 complete range: complete supply pump, vertical motor. When ordering, please specify the material of the main parts. If there are special requirements, please consult with the manufacturer about the technical requirements.

SAP Type Single Stage Double Water Absorbing Level Open Centrifugal Pump

Summary: SAP type centrifugal pump is single-stage and double-suction level open-type centrifugal pump, which is suitable for factories, cities, mines, power stations, farmland, water conservancy projects and other fields. Transporting clear water without solid particles or other liquids with similar physical and chemical properties to water, the temperature of the medium being transported is 0 ~80 C. Parameter Range: Flow Q 72-20000m3/h Head H 6.8-186m Model Description: 10SAP-6J A 10 - Suction caliber 25 excluded (suction caliber 250mm) SAP - Single-stage double-suction horizontal open centrifugal pump 6 - Specific speed 10 excluded integer J - Represents rated speed change A - Represents the first change of impeller outer diameter, A, B, C... The pump is installed horizontally, the pump shell is separated horizontally from the axis, the upper part is the pump cover and the lower part is the pump body. The suction and spitting outlets are all on the pump body below the pump axis. The center line is perpendicular to the axis, so the pump cover can be uncovered and the rotor components can be removed without dismantling the water inlet and outlet pipelines during maintenance. Except for 48SAP-30 pump, which is lubricated by sliding bearings and thin oil, other types of pump bearings are lubricated by rolling bearings and grease, and the end cap of bearing is sealed by skeleton oil seals. Shaft seals are sealed with soft packing and mechanical seals. Major Parts Material: The material of the flow passage parts of the pump is cast iron. If the user needs, the impeller can also be made of cast steel and brass, but it must be specified in the order contract. Pump rotation direction: from the motor end to the pump, for counterclockwise rotation, that is, the suction port in the left, spit outlet in the right. The driving end can also be moved to the other end of the pump according to the user's requirements. At this time, the direction of steering, inhalation and spitting are opposite to the above. Complete range: complete supply pump, motor, coupling. When ordering, please specify the material of the main parts. If there are special requirements for pumps and motors, you can consult with our factory about the technical requirements.

SA, S-type single-stage double-suction horizontal open centrifugal pump

Summary: S, SA type centrifugal pumps are single-stage, double-suction horizontal open-type centrifugal pumps, suitable for factories, cities, mines, power stations, farmland, water conservancy projects and other fields. Transporting clear water without solid particles or other liquids with similar physical and chemical properties to water, the temperature of the medium being transported is 0 ~80 C. Permissible maximum inlet pressure 0.6 MPa parameter range: flow rate Q 72-100 800 m3/h head H 11-140 M model description: 10SA-6J A 10 - suction aperture 25 except (suction aperture 250 mm) SA - single stage double suction horizontal open centrifugal pump 6 - specific speed 10 divides the whole approximate number J - represents rated speed change A - represents the first change of impeller outer diameter, A, B, C... By analogy 300S-19A 300-suction caliber 300mm S-single stage double suction horizontal open centrifugal pump 19-design point head A-represents the first change of impeller outer diameter, A, B, C... The pump is installed horizontally, the pump shell is separated horizontally from the axis, the upper part is the pump cover and the lower part is the pump body. The suction and spitting outlets are all on the pump body below the pump axis. The center line is perpendicular to the axis, so the pump cover can be uncovered and the rotor components can be removed without dismantling the water inlet and outlet pipelines during maintenance. Shaft seals can be sealed with soft packing and mechanical seals. Rotating direction: Seen from motor end to pump, SA pump rotates counterclockwise, that is, the suction port is on the left and the vomiting outlet is on the right. The xxxS-xx pump rotates clockwise, i.e. the suction port is around and the vomiting outlet is left. The driving end can also be moved to the other end of the pump according to the user's requirements. At this time, the direction of steering, inhalation and spitting are opposite to the above. Major Parts Material: The material of the flow passage parts of the pump is cast iron. If the user needs, the impeller can also be made of cast steel and brass, but it must be specified in the order contract. Complete range: complete supply pump, motor, coupling. Pump suction caliber less than 200 mm with common base, the rest do not match the base when ordering, please indicate the main parts material, if there are special requirements for pumps, motors, you can negotiate with the company related technical requirements.

D-type single suction multistage centrifugal water pump

Summary: Type D pump is a single-suction, multi-stage, segmental centrifugal water pump. It is suitable for water supply and drainage in mines, factories and cities. It is used to transport clear water without solid particles or liquids with similar physical and chemical properties as clear water. The temperature of the medium being transported ranges from 0 80 C. The allowable inlet pressure is 0.6 MPa. Parametric range: Flow Q:10-500m3/h head H:33-850m model description: D-type pump has three types of model expression methods, which are as follows: 1) D280-43/84 *5 "D" - single suction, multi-stage, segmental centrifugal water pump. "280" - represents the flow rate of the pump (m3/h). "43" - Indicates the single stage head (m) of the pump. "84" - denotes the year number. "5" - Represents a series. 2) D80-30 *5 "D" - means single suction, multi-stage, segmental centrifugal water pump. "80" - means the diameter of the suction port of the pump (mm). "30" - Indicates the pump's single-stage head (m). "5" - Represents a series. The pump represented by this method is only D80-30. 3) 150D30 *5 "150" - indicating the diameter of the suction port of the pump (mm). "D" - Indicates single suction, multi-stage, segmental centrifugal water pump. "30" - Indicates the pump's single-stage head (m). "5" - Represents a series. Structural type: D-type pump is installed horizontally. Except for D16-60 pump, the direction of suction port is vertical upward, the direction of suction port of other pumps is horizontal. The outlet direction of all D-type pumps is vertical upward. The axial force is balanced by the balance plate. Axle seals are usually packed seals, and mechanical seals can also be used according to user's needs. Except for D85-67, D155-67 pump uses sliding bearing, thin oil lubrication, the rest uses rolling bearing, grease lubrication. Rotation direction: Seen from the motor end, the pump rotates clockwise. Material of main parts: The material of the flow passage parts of the pump is cast iron, and the material of the shaft is 45 steel. Complete range: Pump and motor, base matching supply, can be equipped with a common base or its own base, but also provide accessories (including exhaust cone, gate valve, bottom valve, check valve) and spare parts (including impeller, sealing ring, guide vane sleeve, balance disk, shaft sleeve). When ordering, please specify the material of the main parts. If you have special requirements for pumps and motors, you can consult with our company about the technical requirements.

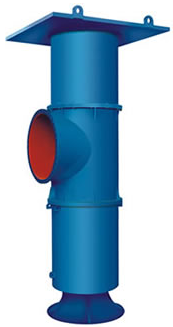

Vertical oblique flow pump

Summary: TKX (S), LKX (S), LBX (S) vertical oblique flow pumps are new products developed by our company in the 1980s by introducing advanced technology from American I-R Company. They are suitable for large thermal power plants and nuclear power plants as circulating pumps, working metallurgical, urban and agricultural water supply and drainage pumps and industrial and mining engineering pumps, which are used for transporting fresh water, rainwater, sewage and seawater below 55 degrees Celsius. Parameter range: Pumps with flow Q 0.20-25 m3/s head H 3-60 m or more can be tested in the test center of our factory. Model Description: 80 LKXC-20A 80-Pump outlet diameter (inch, 2000/25=80) L-means vertical oblique flow pump, T means adjustable blade; K-means pump rotor can be pumped out, B means rotor can not be pumped; X-means pump outlet under the foundation, S means outlet on the foundation; C-pump design sequence; 20-pump design point head; A-means impeller has been cut. Structural type: The pump shaft is installed vertically, the suction inlet is vertical downward, the exhaust outlet is horizontal outward extension, and the rotor components have two forms: extractable and non-extractable. The impeller blade angle of T-type pump can be changed in the operation of the unit. Installation modes are pump and motor installed in two basic layers respectively and pump and motor directly connected in one basic layer. The seal is sealed with packing. Pump suction pool has wet pit type and dry pit type. The axial thrust of the pump is generally borne by the motor, and the small pump can also be borne by the pump itself. The impeller is usually one-stage and can be designed into multi-stage according to the need. The bearings of the pump are rubber bearings and Cylon bearings. When rubber bearings are used, the pump shaft is provided with protective sleeves, which are filled with clean pressure water for lubrication. Material of main parts: Pump shaft is made of high quality carbon steel. The impeller is cast iron or cast steel or stainless steel. The rest are cast iron or steel plate welding. Complete range: complete supply pump, motor and base or mounting pad. When ordering, it is necessary to specify the material required for impeller. If there are special requirements, specific technical requirements can be put forward to the company when ordering.

YJG Vertical Single-stage Single-suction Centrifugal Clean Water Pump

Summary: YJG vertical single stage single suction volute shell centrifugal water pump is a structural improvement of YJ pump. It is suitable for water supply and drainage engineering of large thermal power plant, industry, mining, urban and farmland construction. It is used to transport clean water without solid particles or other liquids whose physical and chemical properties are similar to clear water. The temperature of the transported liquids does not exceed the parameter range of 50 C: flow rate Q 1.0-6.8m3/s head H 13.1-63m model description: YJG44P left-22JA YJG-vertical single-stage single suction volute centrifugal clean water pump 44-suction caliber (mm) is divided by 25, i.e. 44 represents the number of pump suction. The diameter is 1100 mm P, indicating the change of the pump base structure left. From the motor to the pump, the impeller rotates clockwise without marking 22 when it rotates counter-clockwise. The number J obtained by dividing the specific speed of the pump by 10 is the marking of the change of the pump speed A is the marking of the change of impeller diameter, using A, B, C... The difference between impeller models is expressed in terms of I, II... Express. Structural type: The pump is installed vertically with the suction port vertically downward and the spitting outlet horizontally outstretched. The unit is installed in the direct connection of pump and motor, the seal is packed, the bearing adopts rolling bearing, the axial fixing of impeller adopts Huff lock ring structure, the coupling adopts adjustable rigid connection, the impeller is balanced rib structure, and the axial force is borne by the motor. Rotating direction: Seen from the motor to the pump, the pump rotates counterclockwise. If the pump is required to rotate clockwise, add "left" in the prototype number to indicate the difference, and the performance parameters remain unchanged, such as: (YJG36 left -*). Main parts material: impeller: ZG310-570/ZG1Cr13Nil/ZG0Cr13Ni4Mo. Sealing Ring: ZG2Cr13 Axis: 45 Pump Shell: Cast Iron Complete Range: Complete Supply Pump, Motor and Base. When ordering, please specify the impeller material. If there are special requirements for pumps and motors, we can negotiate with the company about the technical requirements.

Summary: Vertical multi-stage condensate pump is a series of products developed by Hitachi Manufacturing Institute in Japan. It is suitable for use as condensate pump in large thermal power plants, including various specifications for 100, 125 (145), 200, 300, 600 and 1000MW turbogenerator units. It can also be used as a pump for pumping other liquids with physical and chemical properties similar to clear water. The temperature of liquids does not exceed 80 C. Parameter Range: Flow Q 230-1920m3/h Head H 74-303m Model Description: B640 (I, II, III) -5B-Initial Double-suction Spiral Centrifugal Condensation Pump 640-Nominal Diameter of Pump Guide Vane Exit mmI-Pump Axial Seal adopts Mechanical Seal II-Pump Body withstands Axial Thrust III-Pump Body withstands Axial Thrust, Pump Axial Thrust The seal adopts mechanical seal 5-pump series structure form: condensate pump is vertical outer cylinder, which has three structural forms: (1) A-initial stage double suction guide vane multi-stage centrifugal condensation pump, (2) B-initial stage double suction helical guide vane multi-stage centrifugal condensation pump, (3) C-initial stage double suction helical oblique flow multi-stage condensation pump unit is installed in direct connection form; It can be borne by the motor or by the pump body. The axial seal of the pump is packed seal, or mechanical seal can be used. Rotating direction: Seen from the motor to the pump, the pump rotates counterclockwise. Material of main parts: First outer cylinder Q235-A/stainless steel impeller 45 steel shell QT450-10 complete range: complete supply pump, vertical motor. When ordering, please specify the material of the main parts. If there are special requirements, please consult with the manufacturer about the technical requirements.

SAP Type Single Stage Double Water Absorbing Level Open Centrifugal Pump

Summary: SAP type centrifugal pump is single-stage and double-suction level open-type centrifugal pump, which is suitable for factories, cities, mines, power stations, farmland, water conservancy projects and other fields. Transporting clear water without solid particles or other liquids with similar physical and chemical properties to water, the temperature of the medium being transported is 0 ~80 C. Parameter Range: Flow Q 72-20000m3/h Head H 6.8-186m Model Description: 10SAP-6J A 10 - Suction caliber 25 excluded (suction caliber 250mm) SAP - Single-stage double-suction horizontal open centrifugal pump 6 - Specific speed 10 excluded integer J - Represents rated speed change A - Represents the first change of impeller outer diameter, A, B, C... The pump is installed horizontally, the pump shell is separated horizontally from the axis, the upper part is the pump cover and the lower part is the pump body. The suction and spitting outlets are all on the pump body below the pump axis. The center line is perpendicular to the axis, so the pump cover can be uncovered and the rotor components can be removed without dismantling the water inlet and outlet pipelines during maintenance. Except for 48SAP-30 pump, which is lubricated by sliding bearings and thin oil, other types of pump bearings are lubricated by rolling bearings and grease, and the end cap of bearing is sealed by skeleton oil seals. Shaft seals are sealed with soft packing and mechanical seals. Major Parts Material: The material of the flow passage parts of the pump is cast iron. If the user needs, the impeller can also be made of cast steel and brass, but it must be specified in the order contract. Pump rotation direction: from the motor end to the pump, for counterclockwise rotation, that is, the suction port in the left, spit outlet in the right. The driving end can also be moved to the other end of the pump according to the user's requirements. At this time, the direction of steering, inhalation and spitting are opposite to the above. Complete range: complete supply pump, motor, coupling. When ordering, please specify the material of the main parts. If there are special requirements for pumps and motors, you can consult with our factory about the technical requirements.

SA, S-type single-stage double-suction horizontal open centrifugal pump

Summary: S, SA type centrifugal pumps are single-stage, double-suction horizontal open-type centrifugal pumps, suitable for factories, cities, mines, power stations, farmland, water conservancy projects and other fields. Transporting clear water without solid particles or other liquids with similar physical and chemical properties to water, the temperature of the medium being transported is 0 ~80 C. Permissible maximum inlet pressure 0.6 MPa parameter range: flow rate Q 72-100 800 m3/h head H 11-140 M model description: 10SA-6J A 10 - suction aperture 25 except (suction aperture 250 mm) SA - single stage double suction horizontal open centrifugal pump 6 - specific speed 10 divides the whole approximate number J - represents rated speed change A - represents the first change of impeller outer diameter, A, B, C... By analogy 300S-19A 300-suction caliber 300mm S-single stage double suction horizontal open centrifugal pump 19-design point head A-represents the first change of impeller outer diameter, A, B, C... The pump is installed horizontally, the pump shell is separated horizontally from the axis, the upper part is the pump cover and the lower part is the pump body. The suction and spitting outlets are all on the pump body below the pump axis. The center line is perpendicular to the axis, so the pump cover can be uncovered and the rotor components can be removed without dismantling the water inlet and outlet pipelines during maintenance. Shaft seals can be sealed with soft packing and mechanical seals. Rotating direction: Seen from motor end to pump, SA pump rotates counterclockwise, that is, the suction port is on the left and the vomiting outlet is on the right. The xxxS-xx pump rotates clockwise, i.e. the suction port is around and the vomiting outlet is left. The driving end can also be moved to the other end of the pump according to the user's requirements. At this time, the direction of steering, inhalation and spitting are opposite to the above. Major Parts Material: The material of the flow passage parts of the pump is cast iron. If the user needs, the impeller can also be made of cast steel and brass, but it must be specified in the order contract. Complete range: complete supply pump, motor, coupling. Pump suction caliber less than 200 mm with common base, the rest do not match the base when ordering, please indicate the main parts material, if there are special requirements for pumps, motors, you can negotiate with the company related technical requirements.

D-type single suction multistage centrifugal water pump

Summary: Type D pump is a single-suction, multi-stage, segmental centrifugal water pump. It is suitable for water supply and drainage in mines, factories and cities. It is used to transport clear water without solid particles or liquids with similar physical and chemical properties as clear water. The temperature of the medium being transported ranges from 0 80 C. The allowable inlet pressure is 0.6 MPa. Parametric range: Flow Q:10-500m3/h head H:33-850m model description: D-type pump has three types of model expression methods, which are as follows: 1) D280-43/84 *5 "D" - single suction, multi-stage, segmental centrifugal water pump. "280" - represents the flow rate of the pump (m3/h). "43" - Indicates the single stage head (m) of the pump. "84" - denotes the year number. "5" - Represents a series. 2) D80-30 *5 "D" - means single suction, multi-stage, segmental centrifugal water pump. "80" - means the diameter of the suction port of the pump (mm). "30" - Indicates the pump's single-stage head (m). "5" - Represents a series. The pump represented by this method is only D80-30. 3) 150D30 *5 "150" - indicating the diameter of the suction port of the pump (mm). "D" - Indicates single suction, multi-stage, segmental centrifugal water pump. "30" - Indicates the pump's single-stage head (m). "5" - Represents a series. Structural type: D-type pump is installed horizontally. Except for D16-60 pump, the direction of suction port is vertical upward, the direction of suction port of other pumps is horizontal. The outlet direction of all D-type pumps is vertical upward. The axial force is balanced by the balance plate. Axle seals are usually packed seals, and mechanical seals can also be used according to user's needs. Except for D85-67, D155-67 pump uses sliding bearing, thin oil lubrication, the rest uses rolling bearing, grease lubrication. Rotation direction: Seen from the motor end, the pump rotates clockwise. Material of main parts: The material of the flow passage parts of the pump is cast iron, and the material of the shaft is 45 steel. Complete range: Pump and motor, base matching supply, can be equipped with a common base or its own base, but also provide accessories (including exhaust cone, gate valve, bottom valve, check valve) and spare parts (including impeller, sealing ring, guide vane sleeve, balance disk, shaft sleeve). When ordering, please specify the material of the main parts. If you have special requirements for pumps and motors, you can consult with our company about the technical requirements.