|

1950 |

-

Kosaka Laboratory started business in Katsushika-ku Tokyo to develop and produce precision measuring instruments.

-

Optical lever surface roughness meter SD-1 developed.

|

|

1953 |

-

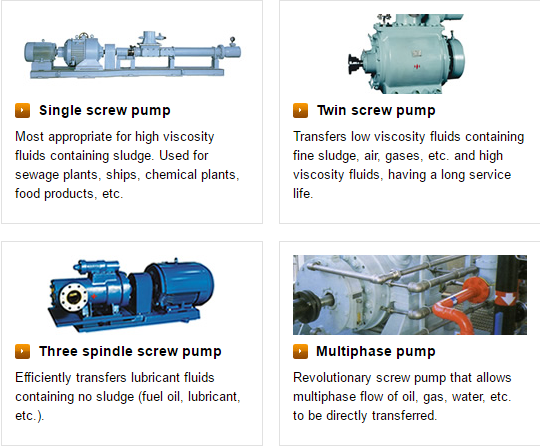

Three spindle screw pump developed.

|

|

1960 |

-

Nation's first electronic Surface Roughness Measuring Instrument SE-1 developed.

|

|

1963 |

-

Universal surface texture measuring instrument with differential transformer SE-3 developed.

|

|

1964 |

-

Misato factory constructed in Misato-shi, Saitama and operation started.

-

Self-centering roundness measuring instrument model EC-1 developed.

|

|

1966 |

-

Centrifugal pump developed.

|

|

1967 |

-

Roundness measuring instrument won the tenth Akashi Memorial Award.

-

Technical license agreement for twin screw pump made with J. H. Bornemann Co. KG., West Germany. (Terminated in 1983)

|

|

1968 |

-

Moka factory constructed on the first industrial campus in Maoka city, Tochigi.

|

|

1973 |

-

Technical license agreement for single screw pump made with J. H. Bornemann Co. KG., West Germany. (Terminated in 1983)

-

Form measuring instrument EF developed.

|

|

1975 |

-

Submerged cargo pump developed.

-

Thin film step measuring instrument ET developed.

|

|

1977 |

-

Surface Roughness Measuring Instrument SE-3FTP with digital analyzer incorporating microcomputer, World's first and VTR cylinder drum Contour Measuring Instrument developed.

|

|

1979 |

-

Tokyo business office opened in Chiyoda-ku, Tokyo.

-

LED die bonder developed.

-

3D Surface Roughness Measuring Instrument with analyzer developed.

|

|

1980 |

-

Articulated space coordinates measuring instrument (Vectoron) developed.

|

|

1983 |

-

The award of Director-general of the science and technology agency won.

Award winner: Seiichiro Kosaka

|

|

1984 |

-

Seiichiro Kosaka, a founder, received a medal of honor.

-

World's first noncontact (optical stylus) Microfigure Measuring Instrument HIPOSS ET-10 developed.

|

|

1986 |

-

Osaka business office opened in Osaka city.

-

Fully automatic glass scriber developed.

|

|

1987 |

-

Fully automatic glass breaking instrument developed.

-

Scanning tunneling microscope (STM) developed in conjunction with National Institute of Advanced Industrial Science and Technology, Japan.

-

Fully automatic roundness measuring instrument EC-3070 developed.

|

|

1989 |

-

Nagoya branch office opened in Nagoya city.

|

|

1991 |

-

The name of Nagoya Branch Office changed to Nagoya Business Office.

-

Portable roughness measuring instrument SE-1100 developed.

|

|

1995 |

-

Compact size Vectoron VMC-1000 series developed.

-

Bundling machine SPA-35 developed.

|

|

1996 |

-

Development and research of multiphase pump consigned by Japan National Oil Corporation.

|

|

1997 |

-

Precision measuring instruments division, Misato Factory ISO 9001, quality management system standard certified.

-

High-accuracy fully automatic roundness measuring instrument EC3400 developed.

|

|

1998 |

-

Side taping machine developed.

-

High performance stage movable type Surface Roughness Measuring Instrument SE4000 developed.

|

|

1999 |

-

Hydraulic equipment division, Misato Factory ISO 9001, quality management system standard, certified.

|

|

2000 |

-

Headquarters transferred to Sotokanda Chiyoda-ku, Tokyo and at the same time, Tokyo business office transferred to said location.

-

Fully automatic Microfigure Measuring Instrument ET4000 developed.

|

|

2003 |

-

Articulated space coordinates measuring instrument (Vectoron) received the award of small and medium enterprise excellent new technology and new product.

-

Hybrid Contour and Roughness Measuring Instrument DSF500 developed.

-

Rotary stage Roundness and Cylindricity Measuring Instrument EC1550 developed.

-

REF100 measuring instrument used exclusively for crankshaft journal and pin corner R developed.

|

|

2004 |

-

Osaka business office transferred due to business expansion.

-

Rotary stage super automatic roundness measuring instrument EC2500 F developed.

-

Rotary detector type roundness measuring instrument for large components EC4100 / EC5100 developed.

-

Large-size fully automatic Microfigure Measuring Instrument for FPD manufacturing process ET5000 / ET6000 developed.

|

|

2005 |

-

Compact size all-purpose Surface Roughness Measuring Instrument SE500 developed.

-

Multi-head fully automatic glass scriber KS series developed.

|

|

2006 |

-

Nagoya business office transferred due to business expansion.

-

Digital Hybrid Contour and Roughness Measuring Instrument DSF800 developed.

-

Contour Measuring Instrument EF550 developed.

-

Vectoron VMC5500 series developed.

|