Tapflo Group, located in Sweden, is an independent family business. We specialize in manufacturing pneumatic diaphragm pumps, centrifugal pumps and other industrial equipment.

Tapflo is a leading pump manufacturer. We strive to provide high quality products of various specifications for industrial applications. Since 1970, Tapflo has been devoted to the treatment of industrial fluids and the design and manufacture of industrial pumps. We have a comprehensive and profound understanding of the needs of users in industrial pumps.

From the beginning of the production of the first pneumatic diaphragm pump, Tapflo has always adhered to the concept of simple structure, reliable performance, a small number of components, easy to maintain products. We are always sensitive to the needs of users and new industries. Therefore, we have been improving the details, materials and accessories of our products, so that our products are constantly improved and improved, more in line with the actual needs of users.

PE & PTFE Pneumatic Diaphragm Pump

PE & PTFE Series

Tapflo polyethylene (PE) or polytetrafluoroethylene (PTFE) pneumatic diaphragm pumps are suitable for almost all types of media, whether viscous, chemically aggressive or containing solid particles.

All Tapflo pneumatic diaphragm pumps have features common to very few components and compact designers. The pump with simple structure can be maintained conveniently and quickly. It can effectively save the maintenance cost of users and shorten the downtime.

Polyethylene Pump (PE)

The wear resistance of high density polyethylene (PE HD) is 6-7 times stronger than that of polypropylene (PP). Therefore, our PE pump can be used to transport abrasive media such as mortar. PE material can withstand most kinds of high concentration acid and alkali liquor. The maximum temperature of withstandable medium is 70 degree C.

PTFE pump

PTFE (pure polytetrafluoroethylene) is an advanced chemical-resistant thermoplastic polymer, which can resist strong corrosive acids, such as concentrated nitric acid and aqua regia. The maximum temperature of withstandable medium is 100 degree C.

Typical application

Industry examples

Chemical Industry: Acid, Alkali, Alcohol, Solvent, Latex, Emulsion

Food CIP Fluids, Spices, Pigments

Pulp & Paper-making Glue, Paste, Adhesive, Dispersant, Resin, Sodium Silicate, Titanium Dioxide

Surface treatment: plating bath, various acids, solvents, anode mud, varnish, enamel

Water treatment, sludge treatment, filter press application, neutralizer, flocculant

Electronic Carrier Liquids, Ultra Pure Liquids, Electroplating Solutions, Mercury, Solvents

Paint & Spraying Adhesives, Auxiliaries, Varnishes, Inks, Paints, Latex, Acids, Resins, Pigments

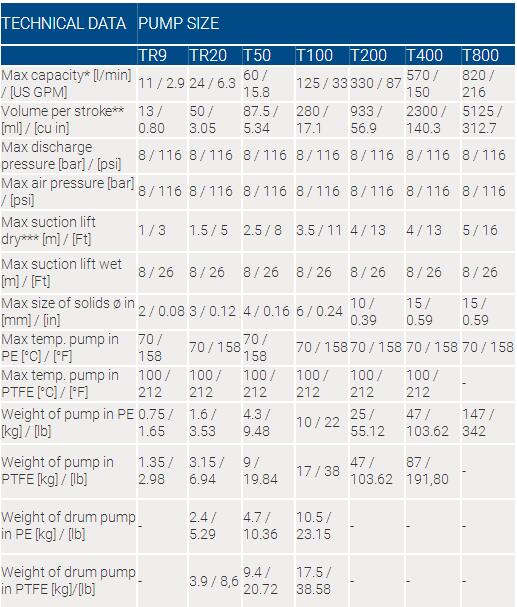

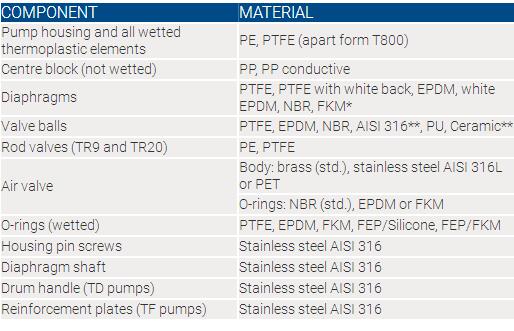

Material of accessories

Component Model: Material

Pump case and all thermoplastic fittings Polyethylene, PE or PTFE

Intermediate (without liquid) PP

Diaphragm TR9: PTFE, FKM

TR20-T800: PTFE, EPDM or NBR

Valve ball T50-T400: PTFE, EPDM, NBR, AISI 3161, PU, Ceramic

T800: PTFE, EPDM, NBR

Conical Valve TR9-TR20: PTFE

Valve Brass/NBR or AISI3161/FKM

O-ring EPDM, PTFE or FKM

Pump shell bolt stainless steel AISI 304

Diaphragm Shaft Stainless Steel AISI 304

Handle of TD Bucket Pump TRD20-TD100: Stainless Steel AISI 316L

TF Booster Pump Reinforcement Plate T50-T400: Stainless Steel AISI 316L

PTFE pump reinforcement plate ordinary pump: PET

ATEX Explosion-proof Pump: AISI 316L

1. Flexible installation

The inlet/outlet tee can rotate 180 degrees. After simply rotating and adjusting the angle, it can be easily connected to the pipeline. Plastic series standard BSP or NPT internal threads, also can choose AISI 316 or other connection.

2. Solid pump body

The pump body is made of rugged PE or PTFE and can withstand high mechanical strength and corrosive chemicals.

3. Design for Chemical Medium

Composite diaphragm with smooth and complete surface ensures that there are no metal parts on the contact surface. It is an ideal choice for transporting chemical liquid.

4. Less gas consumption

The valve design with short air path and no "dead angle" reduces gas consumption and greatly improves work efficiency.