RINGFEDER POWER TRANSMISSION GMBH with its brands RINGFEDER, TSCHAN, HENFEL and GERWAH is a leading company within the international drive technology. International sales representatives and distribution partners around the globe offer solid, reliable solutions for demanding applications in automation and engineering.

As a company always is as good as its staff, RINGFEDER POWER TRANSMISSION sets a high value on solid know how and continuous training.

Service to the customer to us is a promise we take seriously and with the demands of our customers our company grows. Therefore we’re always looking for enlargements to our team.

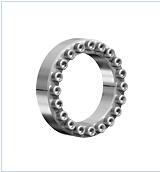

Locking Assemblies

These are the original and premium internal locking devices, fitting inside a component or hub. These units are most commonly used on applications in general engineering to transmit high torques and axial loads. Common types include 7012, 7013.0, 7013.1, 7014 and 7015.0. Most are available in metric series for shafts from 20 mm to 1000 mm dia. and inch sizes for shafts from 3/4” to 7.875” dia.

Locking Assemblies stainless steel

Stainless steel products of RINGFEDER POWER TRANSMISSION have to be used if machinery, components and systems must be cleaned intensely and highly resistant to aggressive cleaning agents is necessary.

Locking Assemblies for bending loads

One of the most demanding challenges on our promise of performance is the belt drum application field. The extreme loads which such components are subject to, especially the high bending moment, coupled with the simultaneous indispensable reliability and longest-possible service life require the highest in engineering know-how.

Locking Assemblies with central lock nut

Locking assemblies with a central nut from RINGFEDER POWER TRANSMISSION boast easy mounting, compact dimensions and a safe connection between the shaft and hub.

Locking Elements

Derived initially from the friction spring technology these tapered rings, type 8006, pair together to form a mechanical wedge between the shaft and component being mounted. Extremely flexible in design, they can be adapted to most applications in general engineering to transmit light to medium torques and axial loads. Available in shaft sizes from 6 mm to 1000 mm.

Locking Elements stainless steel

For highly-stressed shaft-hub connections the shrink fit is unsurpassable. No other shaft-hub connection can offer anywhere near the same performance regarding fatigue strength under alternating torsional stresses. These fits are nevertheless rare, as they call for involved calculations, extremely close machining tolerances, cause considerable trouble when fitting and removing the parts in question, and give rise to problems during repair work (exchangeability, adjustments, centering, etc.).

Shrink Discs

These external clamping devices fit on the hub projection of the component and elastically compress the hub onto the shaft to transmit torque. Designed to be utilized as a single or in a split configuration, these devices transmit high torque. Common types include light duty, medium duty and heavy duty devices like 4051, the new 4061, 4071, 4091 and two piece units such as 4151, 4161, 4171 and 4191 from sizes 13mm to 1000mm bore.

Shrink Discs stainless steel

Stainless steel series - for applications where corrosion resistance and high transmissible torque is required. This new design of shrink disc is made from stainless steel forged rings and uses high strength stainless steel screws. These units are available from 14 mm to 200 mm bore.

Shaft Couplings

Shaft coupling for the rigid connection of two shafts. The design ensures that there is no misalignment whats ever between the shafts and that highly torques can be reliably transmitted. The installation of this coupling does not involve a great deal of work.

Flange Couplings

RINGFEDER® Flange Couplings are the better alternative to press fits. Neither additional components such as keyways or wedges, nor a warming of the outer section and cooling of the inner section are required. The flange coupling is simply pushed onto the shaft and fastened so it is frictionally engaged by tightening the screws in the shrink disc. They transfer torque and bending moments as well as axial and radial forces.

Others

Contact Contact Us

Fax:0084-024-66644590

Tel:0084-024-66644591

Email:sales@big-tree.vn

Add:No.37,Lane 209,Alley 173/37,AnDuongVuong Street,PhuThuong Ward,TayHo District,HaNoi City.