Since 1945 GROB has stood for:

Speed

Reliability

Innovative force

In 1974 our company significantly changed the market – and consequently GROB too, of course – with the cubic linear drive. Apart from these three main features there is a lot more to say about our company. If you want to learn more, just call us or make an appointment to visit us.

We are at your service at all times.

OUR POWERFUL SCREW JACKS - ROBUST AND DURABLE

Screw jacks are genuine all-rounders in drive technology. There is barely an application where they don't enter into the discussion as a drive element. We have been manufacturing linear drives since 1945. The basic principle is both simple and brilliant: a rotary movement is simply converted into an axial movement – in the tightest of spaces.

This is achieved like this: an electric motor drives a worm shaft that causes a worm gear to rotate. The worm gear is provided with a threaded spindle (standard: trapezoidal thread; special version: ball screw) – and the Screw jack is finished.

THE MAIN ADVANTAGE OF OUR SCREW JACKS:

Simple and inexpensive solution in comparison with hydraulic and pneumatic systems.

A defined load can be moved to an exact position at a preset speed.

Several Screw jacks can be synchronised by means of connection shafts and an electronic controller (important, for example in stage construction)

Can be positioned very precisley.

They can exert the same forces in both the pushing and pulling direction.

An economically very interesting solution compared to pneumatic and hydraulic systems.

Many technically ideal and economically interesting solutions can be realised with our modular construction kit concept.

Screw jacks are valued by design engineers as standard machine elements.

THE MAIN ADVANTAGE OF OUR SCREW JACKS:

Simple and inexpensive solution in comparison with hydraulic and pneumatic systems.

A defined load can be moved to an exact position at a preset speed.

Several Screw jacks can be synchronised by means of connection shafts and an electronic controller (important, for example in stage construction)

Can be positioned very precisley.

They can exert the same forces in both the pushing and pulling direction.

An economically very interesting solution compared to pneumatic and hydraulic systems.

Many technically ideal and economically interesting solutions can be realised with our modular construction kit concept.

Screw jacks are valued by design engineers as standard machine elements.

CUBIC SCREW JACKS – 2.5 KN TO 500 KN

The housing form is in the name: it is cubic, i.e. smooth. All surfaces are machined; therefore this design offers a wide range of possibilities for attachment to various constructions. We can realise payloads from 2.5 kN to 500 kN.

The cubic Screw jacks bear the designation MJ or BJ. A total of 11 sizes are available in the standard version.

CLASSIC SCREW JACKS – 0.5 TO 2,000 KN

The housing form of this Screw jacks is in its name: Classic, as in classic design. As opposed to the cubic design, the Screw jacks from this series can accept higher loads of up to 2,000 kN. Due to the design, you cannot attach any construction elements to the housing.

The ClassicScrew jacks bear the designation MC. A total of 14 sizes are available, each in a travelling nut version and a basic version.

HIGH-PERFORMANCE CLASSIC SCREW JACKS – 5 KN TO 1,000 KN

Here, too, the name reveals what's inside the drive. These high-performance Screw jacks are tailored for particularly dynamic and demanding areas of use where standard Screw jacks are not suitable due to the simple construction.

Special feature of the HMC drives: The housing form is optimised with cooling fins for perfect heat dissipation. An optimised duty cycle can thus be achieved. The worm gear runs in an oil bath. The heat is dissipated better and distributed over the entire drive as a result.

The consequence of that is that we can realise higher speeds and loads. The high-performance drives bear the designation HMC. They can lift payloads from 5 kN to 1,000 kN.

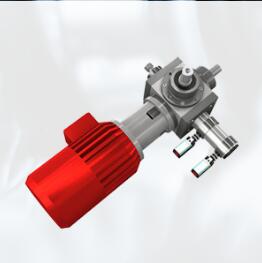

HIGH-SPEED SCREW JACKS – 2.5 KN TO 90 KN

As a supplement to our range of Screw jacks, GROB high-speed Screw jacks offer an extension to the range of uses of our Screw jacks. As opposed to the normal Screw jacks, bevel gear transmissions are used.

The range encompasses three sizes, with the transmission ratios 1:1, 2:1 and 3:1. Thanks to the high efficiency of the bevel gear sets, the total efficiency of the GROB high-speed Screw jacks is around 75 % with ball screws and around 40 % with trapezoidal threaded spindles.

In the case of the trapezoidal threaded spindles, the high-speed Screw jacks is filled with grease; in the case of the ball screw it is filled with oil.

Others

Contact Contact Us

Fax:0084-024-66644590

Tel:0084-024-66644591

Email:sales@big-tree.vn

Add:No.37,Lane 209,Alley 173/37,AnDuongVuong Street,PhuThuong Ward,TayHo District,HaNoi City.