Contact Contact Us

Fax:0084-024-66644590

Tel:0084-024-66644591

Email:sales@big-tree.vn

Add:No.37,Lane 209,Alley 173/37,AnDuongVuong Street,PhuThuong Ward,TayHo District,HaNoi City.

High Performance Slurry Pumps

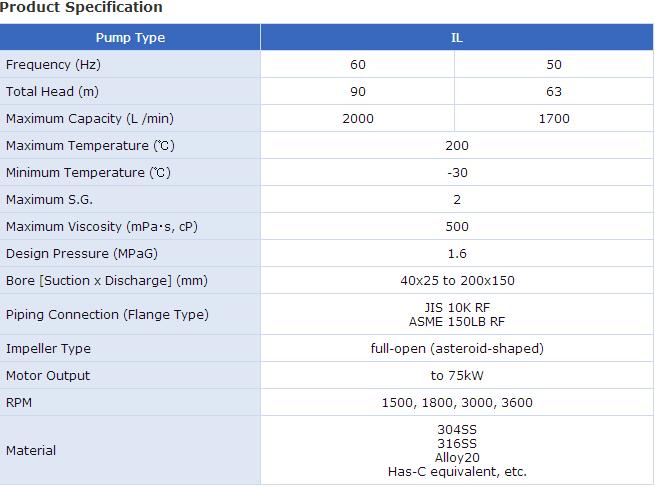

IL

Gala Pump

With a specific structure of its own, "Gala Pump" resolved the typical pumping-up inability problem that is caused by dry run of centrifugal pumps. It eliminates the abnormal thrust completely that usually occurs during dry run. As a result, no excessive force is applied to the pump shaft, nor does abnormal vibration occur. In addition, the unique structure of impeller contributes to less fluid loss and reduction of running cost by 10%.

"Gala Pump" is an innovative stainless steel pump that can be used for slurry application.

By adopting the unique asteroid-shaped full-open impeller of our own, it is easier to eliminate the air bubbles which are very likely to accumulate inside an impeller in aeration operation.

Gland packing and mechanical seal are available for shaft seal. External flushing is adopted to prevent dry run of shaft seal parts during aeration operation.

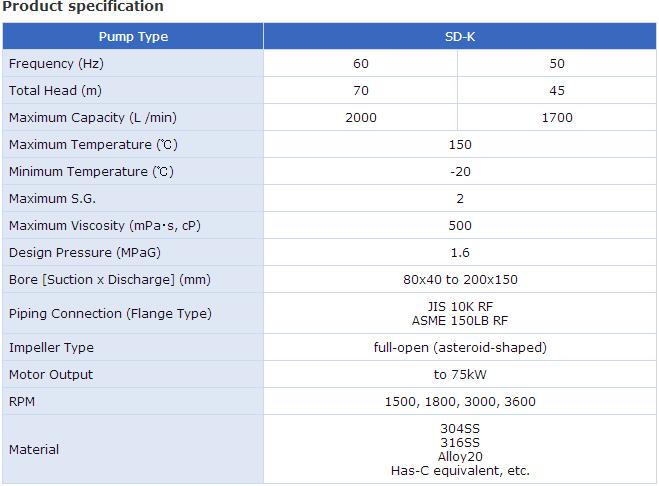

SD-K

Scatter Pump

There is a number of conventional high-performance equipment with mono-function of mixing or chopping. However, on the production line that requires a variety of processing steps, when it comes to installing the equipment with the respective application, the burden of maintenance, initial and running cost become large, yet it is difficult to fix the performance balance of each device. Sanwa, type SD-K is completed as a multi-purpose distributed pump. It is aggregated with 4 different functions, chopping, mixing, dispersion and pumping.

Chop the solid in the fluid into pieces. Eliminate the clogging of the fluid feed line.

Concerning stirring and mixing capability of the cutter, "Scatter Pump" is way ahead of conventional blender and agitator.

It is most suitable for the circulation pump of the reaction tank. The prominent stirring and mixing capability is to shorten the reaction time and greatly increase production volume.

It is very useful as a slurry pump of high head.

Excellent chopping capability, highly efficient as a pump also.

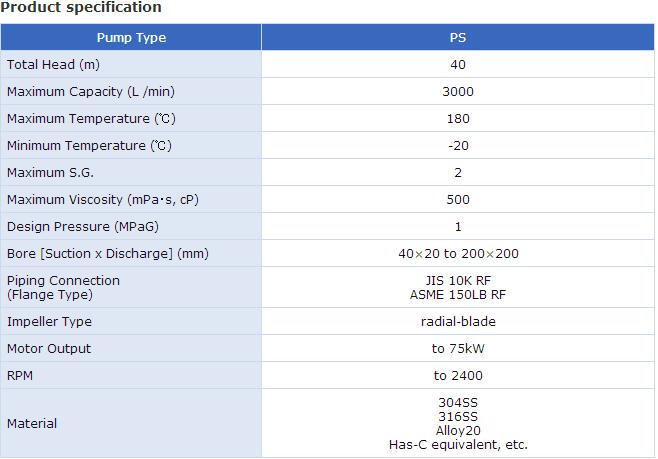

PS

Through Pump

"Through Pump" Type PS, which can transport slurry without breaking down the containing solids, is designed and manufactured on the basis of a non-traditional theory -Vortex Induction Theory. The crystalline material doesn't contact the impeller directly and will not be broken down or damaged. And a slurry comprising solid under the size of the pump discharge can be pumped smoothly.

The impeller blades are arranged in a radial fashion, and the clearance between impeller and casing has been designed with sufficient consideration.

Therefore, there's no need to worry about the big solids, crystalline materials or slurry in a fiber fashion twining around the impeller.

With no extra protrusions on the inner surface of casing and suction bore being made particularly bigger, the liquid can smoothly flow through the suction in a relatively slow speed, therefore nothing like crystal fragmentation caused by contact between impeller and the liquid or so would ever occur to break or damage the solids.

Variable speed motor or inverter motor can be utilized to adjust pump capacity and total head, therefore discharge valve is unnecessary. Optimum operation can be carried out in accordance with the operation rate of the process.